In 2016 I got a Monoprice Select Mini 3D Printer (model number 15365) for $200 USD. That was incredibly affordable for a 3D printer back then. That printer only gave me disappointments. I was never was able to print anything completely with it. My main problem was adhesion. The only help I got was online forums (there was a really active Facebook group about it). Debugging and trying different solutions without any success was not fun. It ended up just accumulating dust and occupying space in a corner.

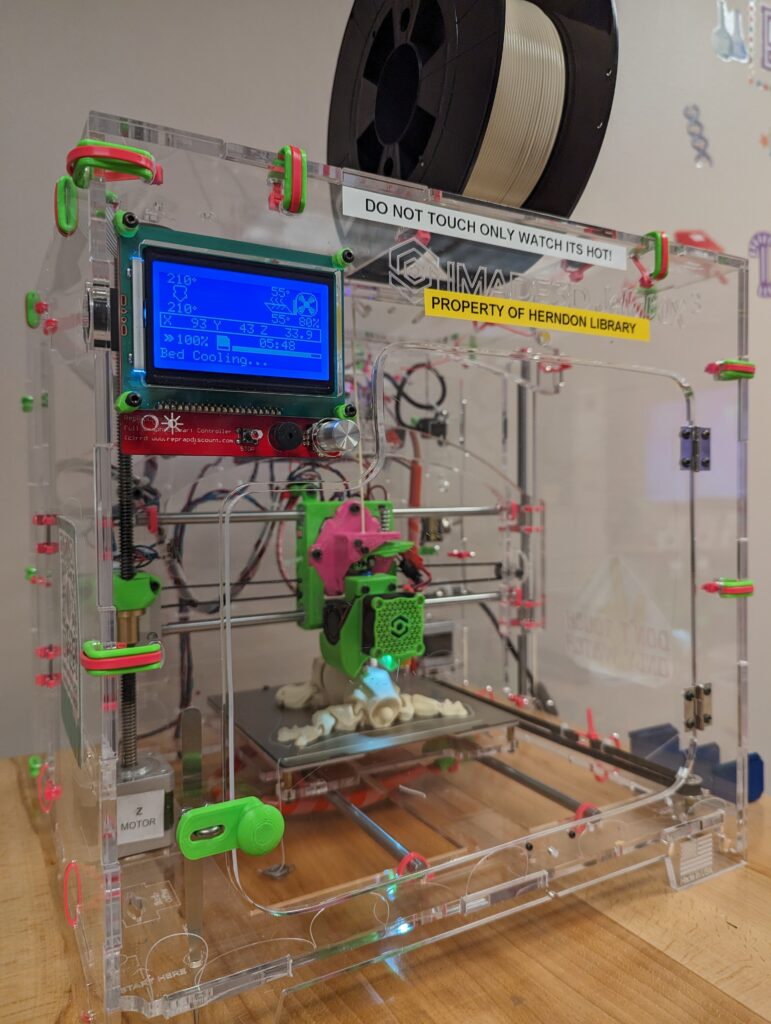

Years later I found that my local library had working and calibrated 3d printers that I could just use. Just upload a .stl file and they would just email me when the print was ready. Also, for free. I tried it and it worked really well.

So I filled some paperwork and donated my Monoprice Select Mini 3D Printer to the library. They also had a lot of other cool technology programs going on. From now on if I need to print something I know I could just use the library. I promise myself I would not mess with 3D printers themselves anymore.

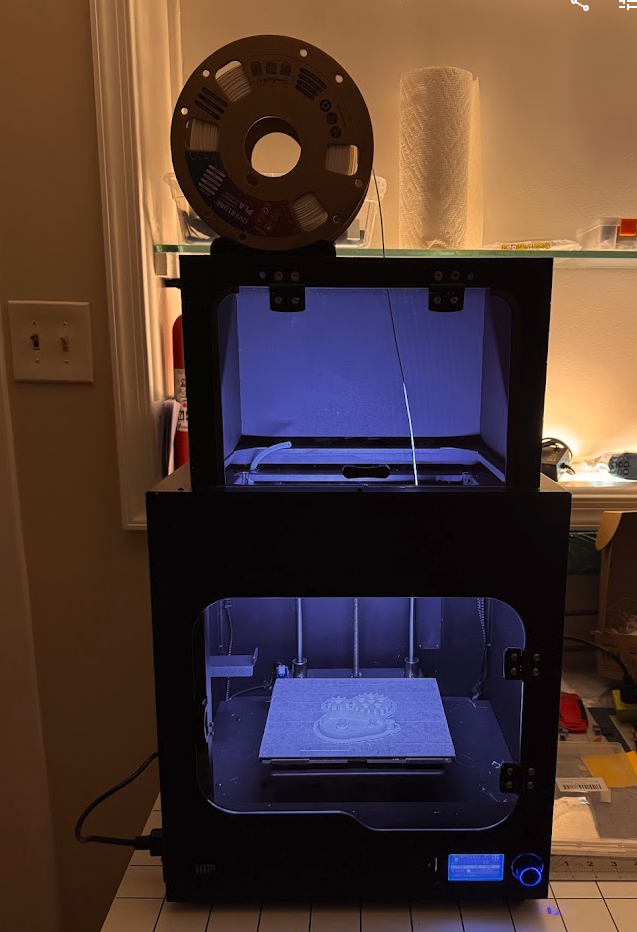

Now in 2025, someone in the neighborhood was looking to donate their Monoprice Maker 2 Ultimate 3D printer. Just when I thought I was out, they pulled me back in. I got it from his hands, bought a spool of PLA Filament and started playing with it.

Monoprice Maker 2 Ultimate 3D printer technical specifications:

- Maximum build volume: 200 x 150 x150mm

- Filament diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Maximum Nozzle Temperature: 250°C

- Maximum Build Plate Temperature: 100°C

- Printing Speed: 20 ~ 150 mm/sec

- Positioning Accuracy: XY Axis: 0.011mm, Z-Axis: 0.0025mm

- Supported Filament Types: ABS, PLA, PLA Pro, TPU, TPE, PET, Metal fill, Wood fill, etc.

- Supported Software: Wiibuilder, Cura, Simplify3D, Slic3r, Kisslicer

- Supported File Formats: .STL, .gcode, .OBJ

- Print Interface: USB, microSD card

- Input Power: 24 VDC, 10A

- AC Adapter Input Power: 100 ~ 240 VAC, 50/60 Hz

- Maximum Power Consumption: 200 watts

- Dimensions: 15.0″ x 13.4″ x 16.5″ (380 x 340 x 420 mm)

- Weight: 33.1 lbs. (15kg)

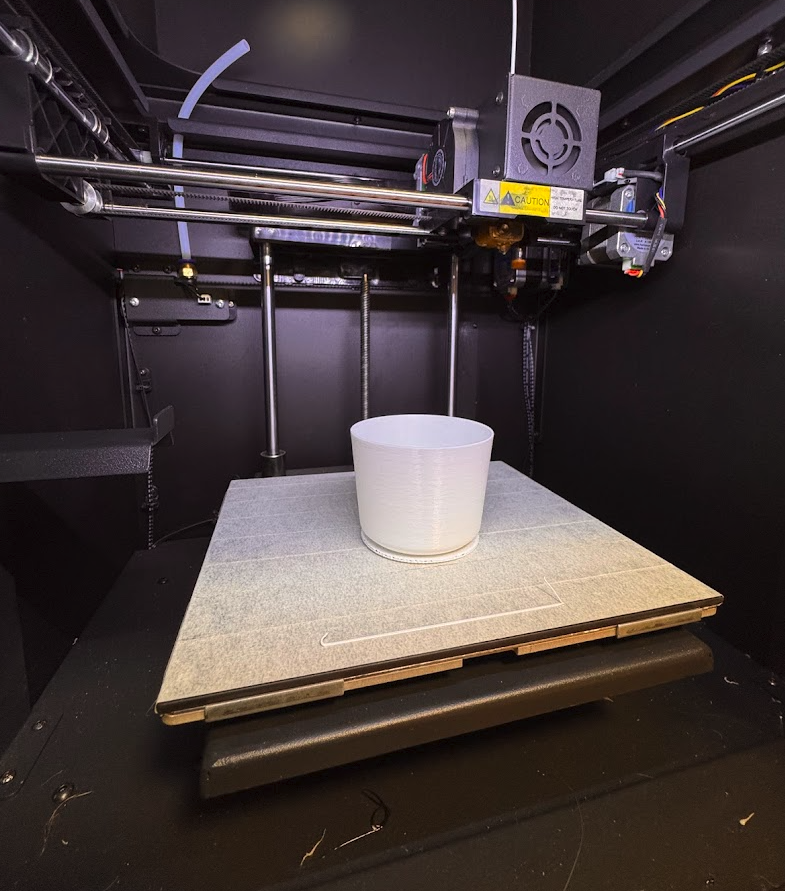

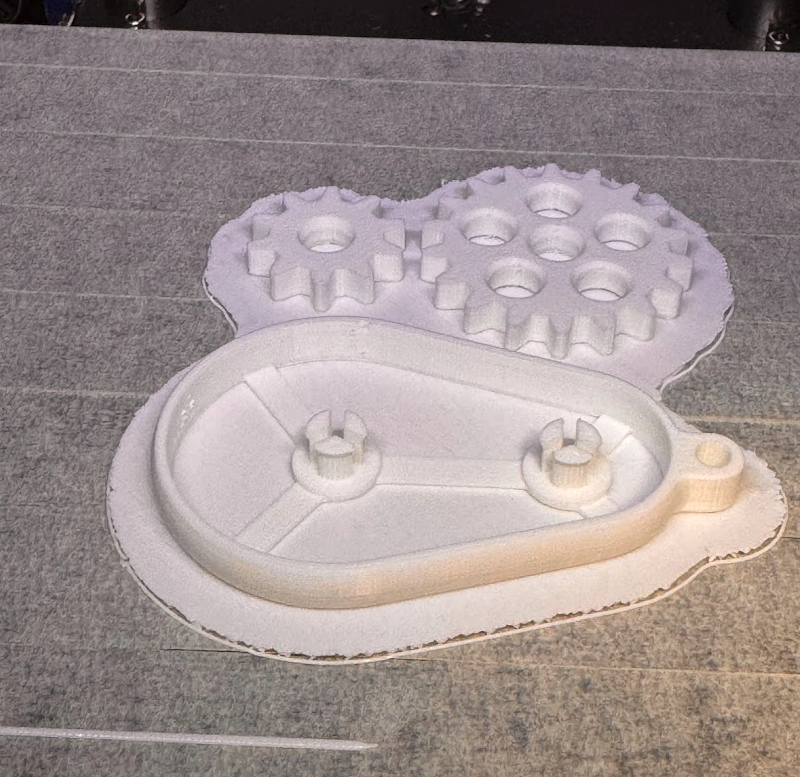

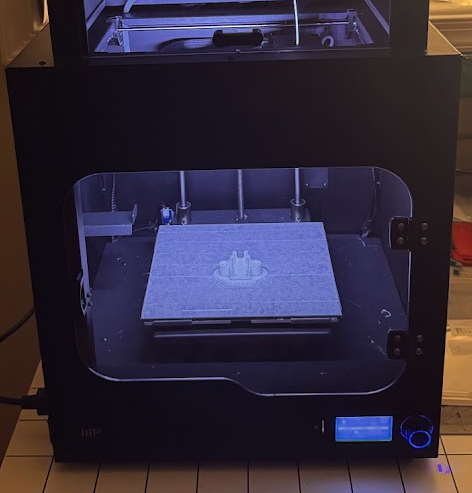

I started just printing whatever gcode it had on its sdcard. My first prints were just adhesion failures again. That’s when my previous experiences from before were handy. I re-applied painters tape on the print bed, then the prints started to get further and further before failing. Then I got my first complete 3d print.

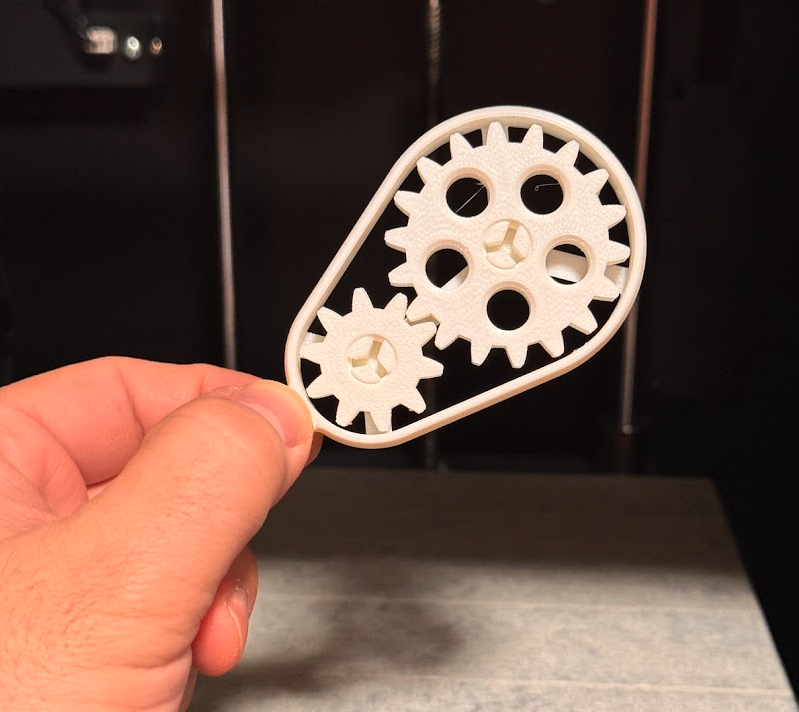

Then I started trying with Thingverse stl objects, cutting them in Ultimaker Cura and printing my own gcodes. Here is the catch: the Monoprice Maker 2 Ultimate is a rebranded Weedo F150s. After I configured Cura to use a Weedo F150s the gcodes produced started to print with success.

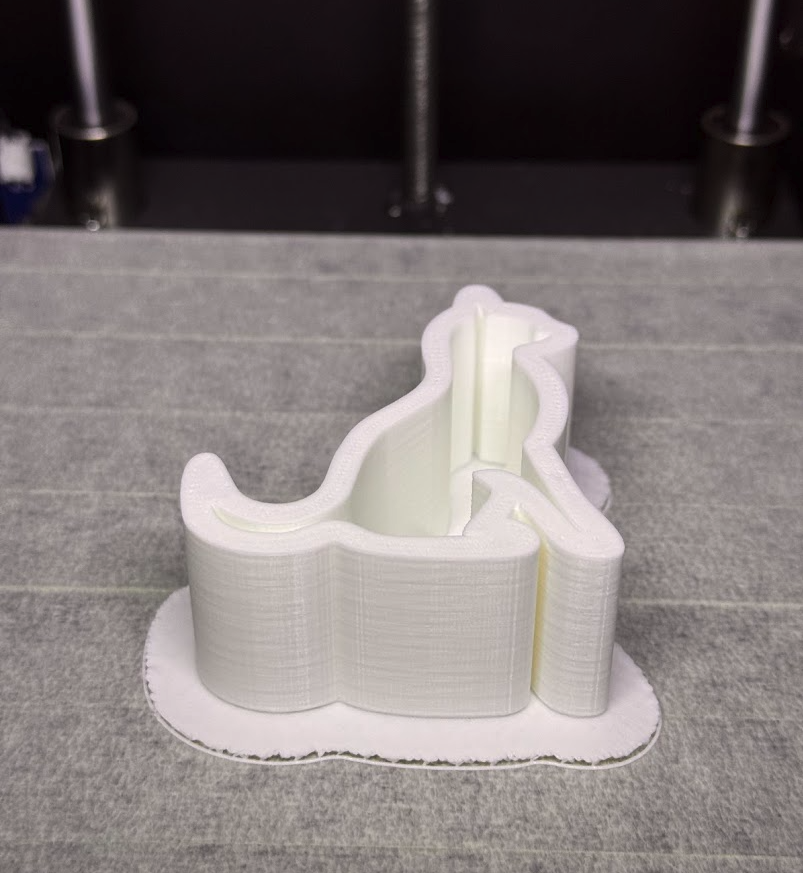

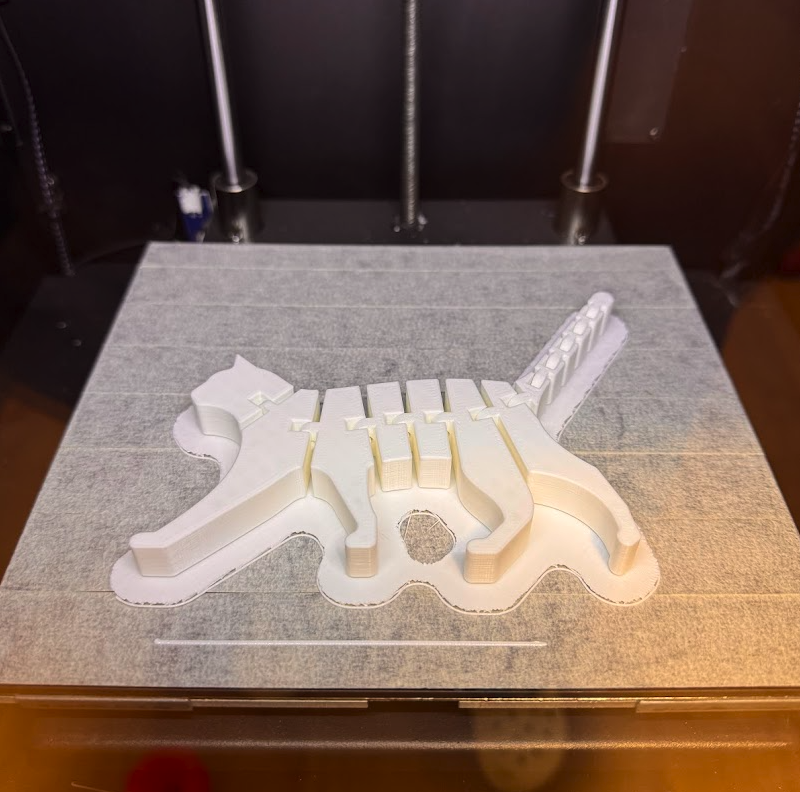

I have now printed this flexi cat that took almost 6 hours. Do you know what I never got it printing correctly? That 3DBenchy that I always tried to print on my first printer. On this one it always causes the printer to shift layers and fail. Surely with some fine tuning of the parameters I can get it right but the lesson learned here is that sometimes a simple vase is a much better goal. Also, sometimes a 3D printer have more success printing larger objects rather than small ones.